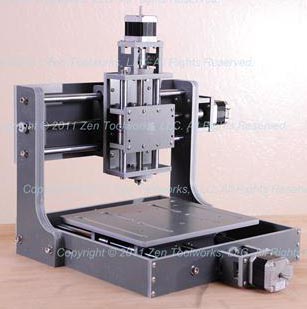

Inexpensive CNC routers are widely available, typically costing about $250-300. The following describes how I now use them to do fretboard and peghead inlays. I discovered that they can indeed produce very acceptable results, though they have their own learning curve and techniques to master. So I decided to explore whether the current generation of small, inexpensive CNC routers might be able to give satisfactory results for inlays. But we luthiers already use lots of technology, including bandsaws, jointers, thickness sanders and the like, specifically to speed tasks that would otherwise be time-consuming and difficult (you don’t find too many folks resawing their backs and sides by hand any more). Part of me has resisted this sort of automation, as I don’t want to turn my craft into a push-button activity. With the advent of inexpensive computer-controlled (CNC) routers, I got to thinking that maybe it would be worth bowing to the inevitable and using technology to help with this aspect of lutherie. But I’ve been finding that I’m less and less enjoying the process of inlaying – the results, sure, but the work, not so much. I’ve compensated for aging eyes with multiple layers of magnifying eyepieces, and for the (lack of) fine motor skills with frequent rests. As I’ve aged, both of these have gone in the wrong direction.

This unfortunately makes the operation tedious and time-consuming, requiring good eyesight and steady hands.

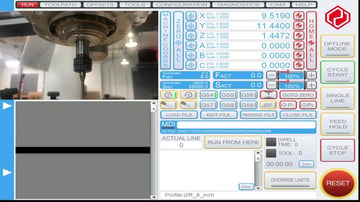

The routed recesses need to closely match the pieces to be inlaid, requiring precise scribing of the outlines and careful routing under close magnification to make sure there aren’t gaps between the inlays and the pockets. For the small-ish designs on a guitar, the design elements need to be cut precisely so they don’t have an uneven appearance, necessitating very fine lines in the design and close cutting to the lines. To get good results, very fine precision is needed. Rout the inlay cavities with a Dremel or other small routerīird’s-mouth and jeweler’s saw used to cut out fretmarker inlays.Scribe the outline of the cut-out pieces onto the surface to be inlaid with an Xacto knife.Cut the design out from the inlay material using a jeweler’s saw and a bird’s-mouth platform.Design the inlay (using paper and pencil, or with a computer drawing program).The standard approach to doing any type of inlay is the following: They’re also used on the fretboard as fret position markers. They’re frequently used on the peghead, to display the name or initials of the builder. Loosely defined, an inlay is a design consisting of a cutout of one material glued into a recess in another. Inlays are a nice way to customize a guitar.

0 kommentar(er)

0 kommentar(er)